|

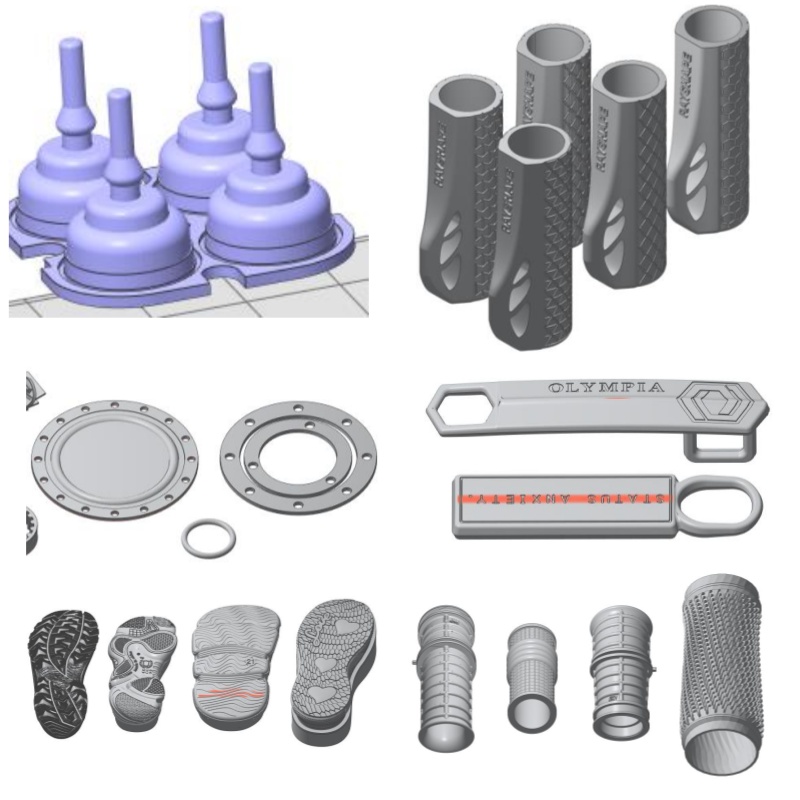

Elastomer partsSilicone - based 3D printed elastomers exhibit exceptional flexibility, durability, and precision, making them ideal for prototyping and functional testing. These materials offer high elasticity, enabling parts to withstand repeated bending, compression, or stretching while retaining their original shape. They also demonstrate excellent tear resistance and chemical stability, ensuring longevity in demanding applications.

Collect

Features

Details

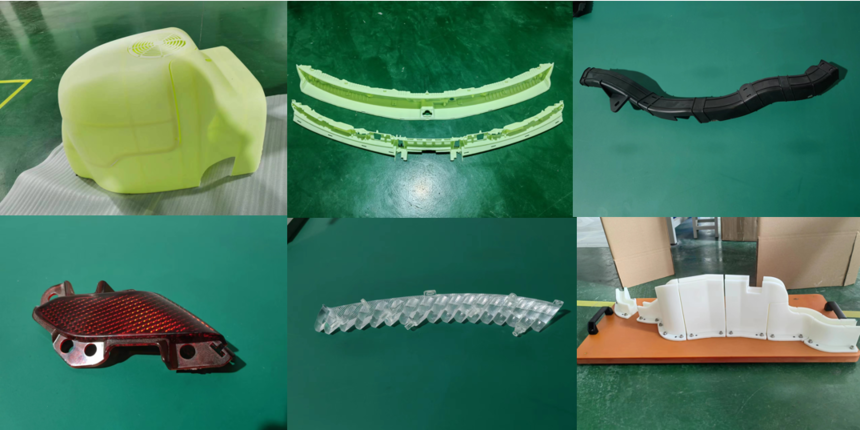

The development potential of 3D printing elastomers is gaining significant momentum as additive manufacturing continues to revolutionize industrial production. Photocurable elastomers, with their unique ability to withstand repeated mechanical stress while maintaining dimensional stability, are reshaping industries such as automotive, healthcare, and consumer goods. Their transparency, high elasticity, and tear resistance enable applications ranging from customizable medical devices and flexible electronics to intricate shoe molds and ergonomic grips. The global market for 3D printing elastomers is projected to grow at a compound annual growth rate (CAGR) of over 20% through 2030, driven by increasing demand for lightweight, durable, and cost-effective solutions. Key advancements in resin formulation and curing technologies are overcoming traditional limitations like brittleness and slow production speeds, expanding possibilities for on-demand prototyping and end-use part manufacturing. As sustainability becomes a priority, the reduced material waste and energy efficiency of 3D printing further solidify elastomers' role in the future of smart manufacturing.

Reference videos of application Elastic balls Automotive parts |